My BMW K75 motorcycle’s front brake light switch (part 61311459569) was failing. I removed it from the bike, and confirmed by multimeter that the switch made no contact whether depressed or not. I tried to wiggle the contacts and spray it with some electronics cleaner, and although I got it working intermittently, I couldn’t really get it to work that way.

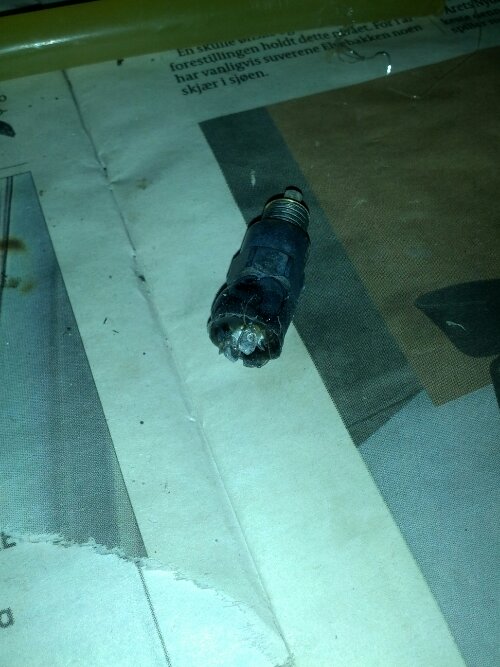

In the end, since a non-working switch is just worthless I determined to make a last ditch attempt: Dismantle the switch completely and then see if I could rebuild it. The problem was that the switch core was mostly set in plastic inside the brass casing, and I was unable to pull it out of there. So I took my propane torch and melted the plastic, leaving just the metal pieces (and the plastic push-rod, thankfully):

The way this works is that the brass ring goes onto the thinner end of the plastic pin, which then presses against the spring (the thicker end is the actual switch pin that is pressed against by the brake lever). The two metal contacts press against the brass ring from opposite sides, causing a closed electrical contact. When the pin is pressed, the thick part of the plastic pin takes on the position of the brass ring, breaking the circuit.

Now, the challenge is to put this toghether in a way that will hold up to some wear and tear.

First, I take a piece of plastic tube (a piece of wire insulation) that fits loosely around the spring (this is already in place in the picture above). A tiny piece of plastic (actually a piece of smaller diameter insulation) is superglued into one end to stop the spring from just going through the tube. Now, the two contacts can be superglued onto the tube:

In the picture below I’m holding all the pieces in the normally closed circuit position, and you can see both contacts touching the brass ring:

In the next picture the pin/button is pressed, and the circuit is broken (which would cause the brake lights to turn on):

At this point I take a small piece of epoxy putty and encase the contacts, tube, and spring, such that the whole assembly fits snugly into the brass housing:

I then fix the assembly to the housing with superglue (I tried hot-melt glue first, but that didn’t work). Doing this, it was critical to fix the assembly at the correct position such that the switch would be «normally closed» as it should be. Since you can’t look inside the switch to get the positioning correct, I keep the contacts hooked up to a multimeter while gluing. It’s a bit tricky…

Finally, wrap some electrical tape around the outer diameter of the switch housing and fill the gap between the tape and epoxy with black hot-melt glue:

Electromechanically this seems to work quite well. It remains to see if it’ll work on the bike and for how long, but I’m hopeful it’ll work for quite some time.